We Design,

We Manufacture,

We Deliver!

15 Years of R&D and Manufacturing Experience

Chuancheng Precision – A technology-driven manufacturer of thermal protectors, thermostats, and micro switches

Chuancheng Product Range

With an engineer’s precision, day upon day, year over year, We forge certified excellence into every component.Through thermal innovation’s reliable embrace,We safeguard critical systems for global industries and living spaces.

Open-Type Temperature

Controller SP6

Insulation Resistance

Contact Resistance

Lifespan

Leakage Characteristics (PTI)

≥100MΩ

≤50mΩ

10,000+cycles

175

Backpack-style Temperature Controller

Patent

Operating Temp

AC 250V/12A

Lifespan

ZL 202123189766.3

50°C-160°C

AC125V/16A

≥10000

KST Adjustable Thermostat

Operating Temp

AC 250V/16A

Lifespan

Operating Ambient Tep

180°/270°

AC125V/16A

≥100000

125°C

CCS8 Overheat

Protector

Patent

Operating Temp

AC 250V/8A

Lifespan

ZL 2014 2 0044802.8

50°C -150°C

≥100mΩ

≥10000

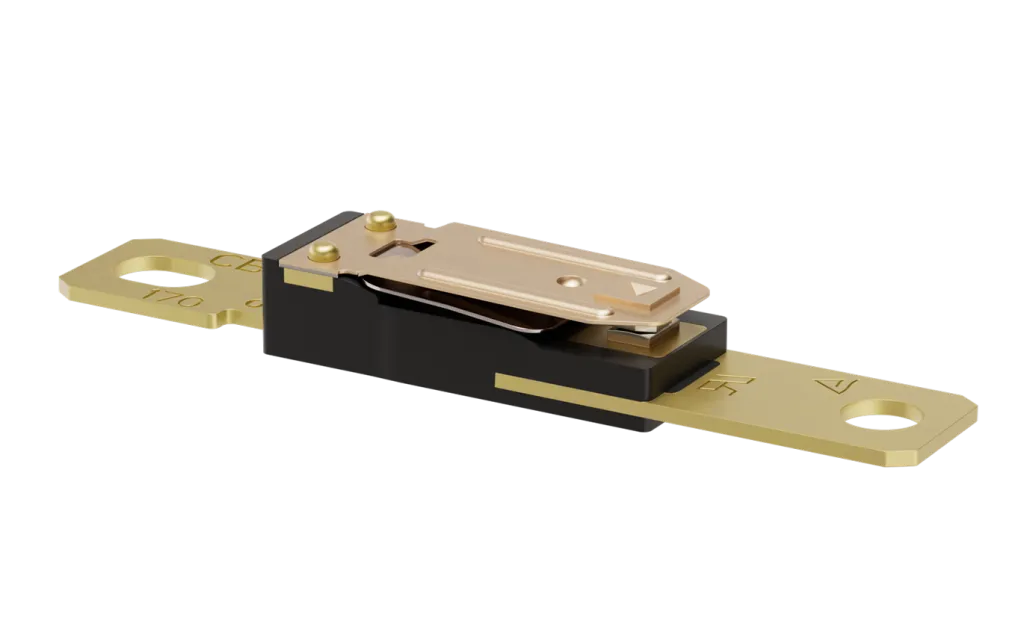

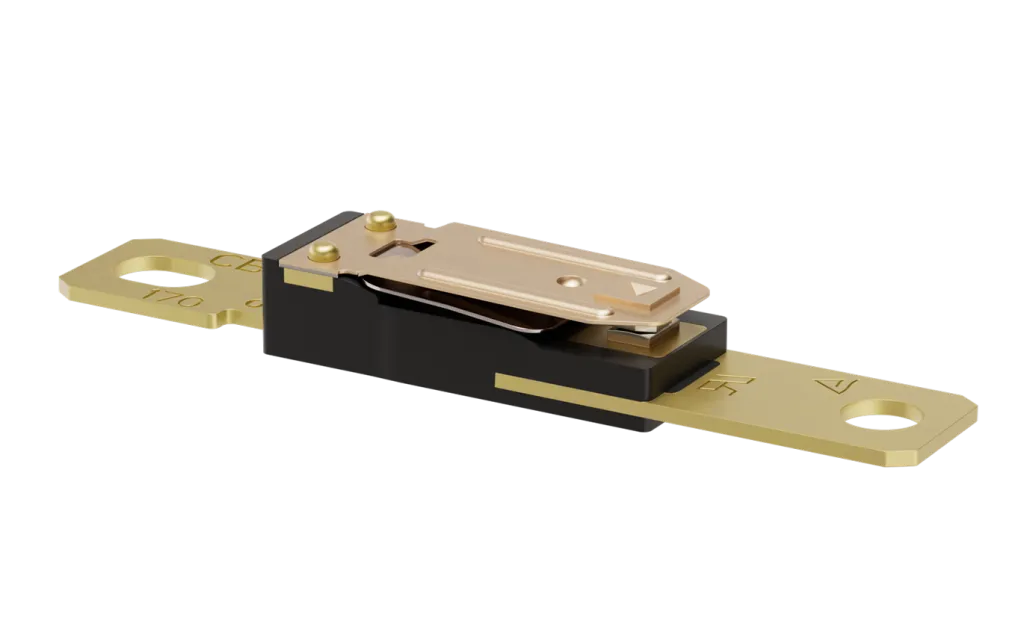

Open-Type Temperature

Controller S6P

Patent

Operating Temp

AC 250V/16A

Lifespan

ZL 202230254498.X

45°C -170°C

AC125V/18A

≥10000

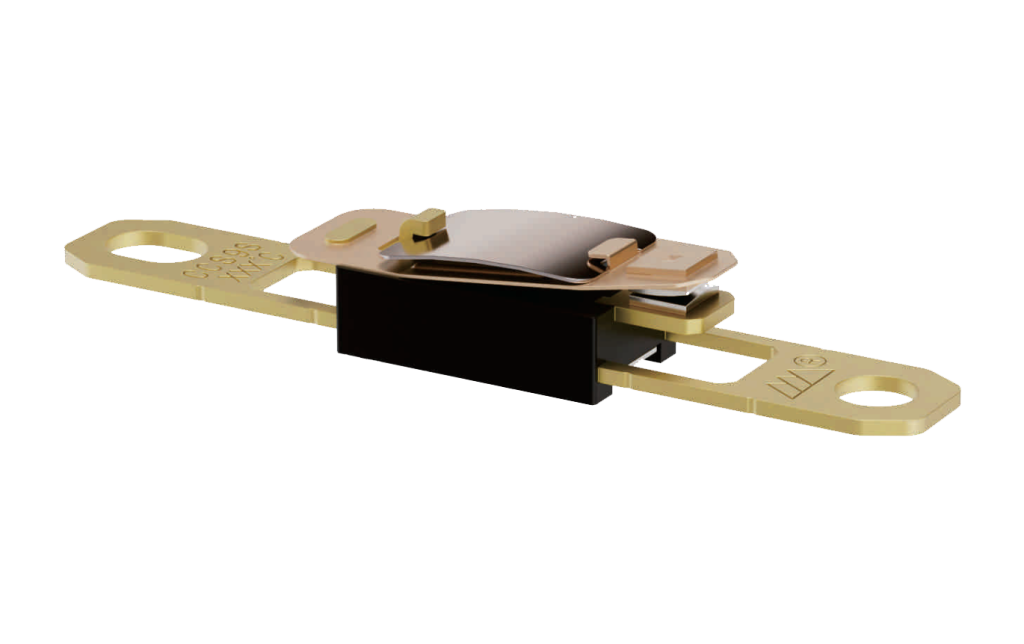

Snap-action Thermostat KSD301

Patent

Operating Temp

AC 250V/16A

Lifespan

ZL202323031904.4

45°C -170°C

AC125V/30A

≥10000

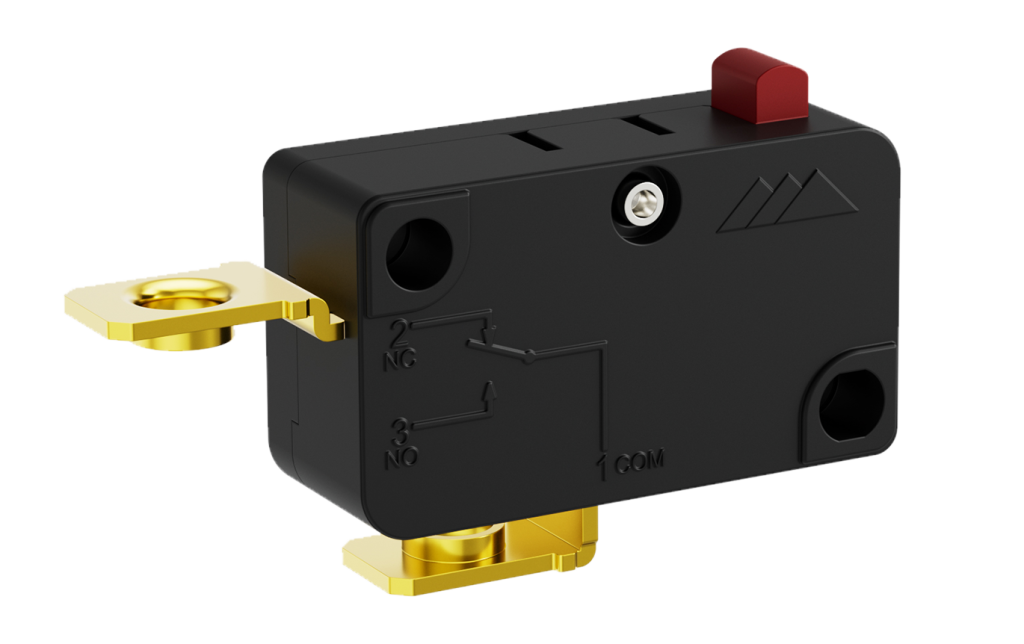

Micro Switch

CCY

Patent

16(6)125

Operating frequency

Life span

ZL 2021215877997.1

250V AC

60/minute

≥1,000,000

TECHNICAL EXCELLENCE

60+ Patents

130+ certifications

Dedicated R&D center with standard lab.

EXPERINCE

15 years of deep industry expertise.

Engineering-led solutions for complex challenges.

COST EFFICIENCY

lower TCO via automated precision.

Value engineering that reduces component costs without compromise.

QUALITY

Zero-Compromise Quality

0.8% Defect Rate: Industry-Leading PPM Performance.

Authoritative certification

Safe and reliable

Won various authoritative patent certifications

Follow the latest developments in the industry

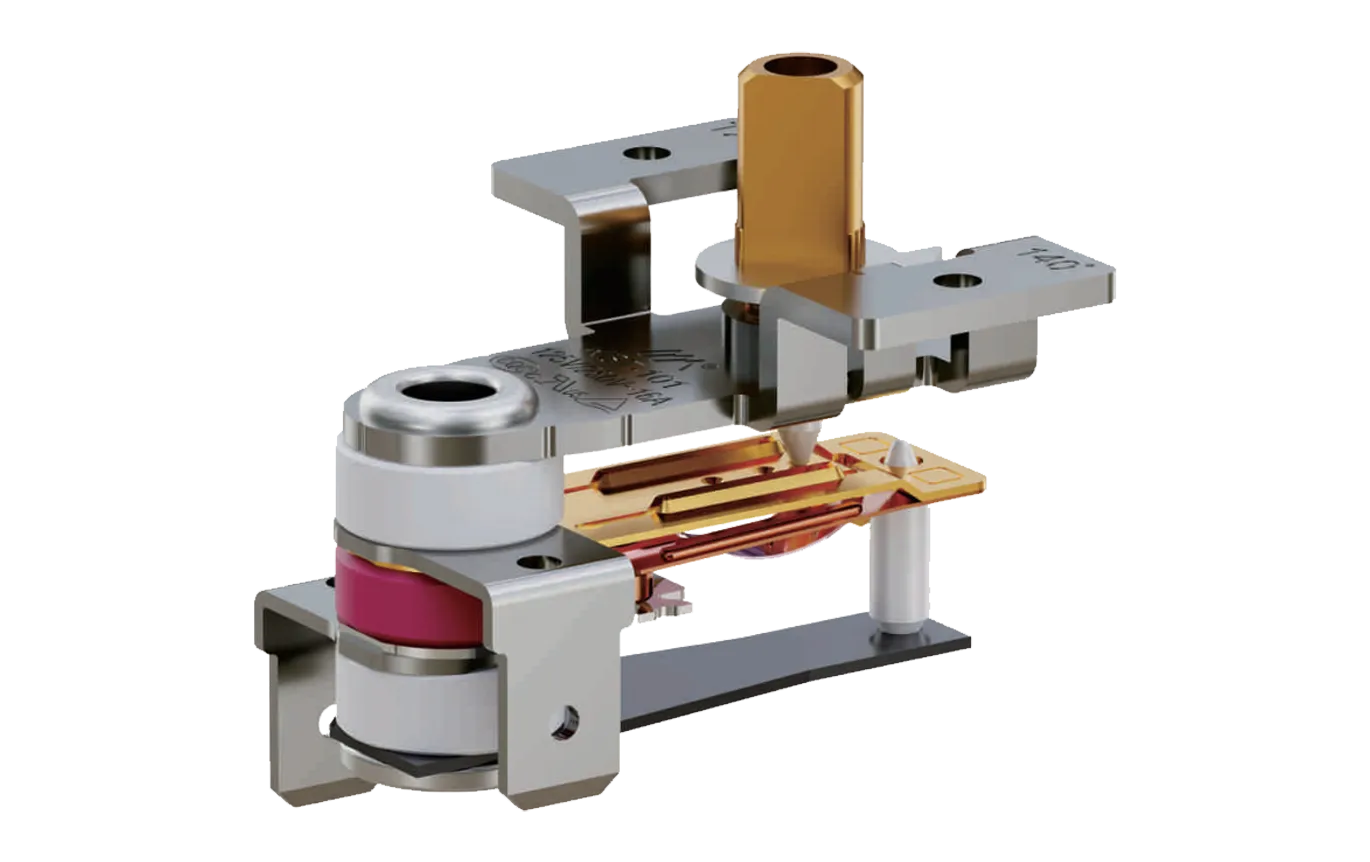

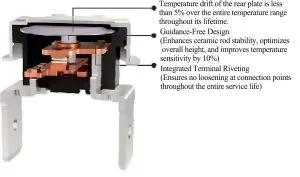

Innovations and Advantages of Snap-action Thermostat Explained in Detail

The core component of a snap-action thermostat is the bimetallic disc: a circular, pan-shaped bimetallic strip formed through stamping and heat treatment. It serves to provide the preset temperature point and the force for actuation. 1.Product Appearance 2.Product Structure 1.Auto-reset 2.Manual reset

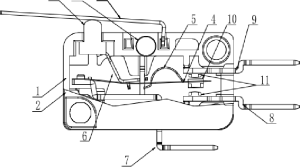

Innovations and Advantages of Micro Switches Explained in Detail

1.Product Appearance 2.Product Structure 1.Base 2.Outer casing 3.Button 4.Movable plate 5.Clips 6.Support rod 7.COM 8.N.O 9.N.C 10.Moving contact 11.Stationary contactor 12.Rod 13.Rivet 3.Structural Advantages

What is a Hair Dryer Thermostat Switch? The Unsung Hero of Safe Styling

You enjoy the consistent, warm airflow from your hair dryer every day, but have you ever wondered what prevents it from overheating and becoming a safety hazard? The answer lies in a small but vital component: the thermostat switch. This article explains what it is, why it’s indispensable, and how it works to protect both your

Key Technical Parameters of Motor Thermal Protectors: A Buyer’s Guide

Selecting the right thermal protector is critical for ensuring the longevity and safety of an electric motor. Beyond understanding its principle, delving into its technical parameters is essential for engineers, purchasers, and technicians. This guide breaks down the key specifications you need to know when evaluating a motor thermal protector. Rated Operating Voltage (Ue) and Current (Ie)

How Does a Thermal Overload Protector Work? A Deep Dive into Its Operating Principle

In the world of electrical engineering and appliance design, safety is paramount. One component stands as a silent guardian against one of the most common hazards—overheating. This component is the thermal overload protector. But how does this critical device actually work? This article breaks down its fundamental operating principle. The Core Principle: Converting Heat into Mechanical

Thermal Protectors vs. Current Overload Protectors: Explaining the Key Differences

In the realms of electrical safety and equipment reliability, Thermal Protectors and Current Overload Protectors are two key guardians. Although their ultimate goal is to prevent equipment damage, their working principles and application scenarios are fundamentally different. Choosing the wrong protector can lead to ineffective protection or even equipment failure. This article delves into the differences between the two