Explore how motor overheat protectors work. This guide explains the principles of bimetallic strip & thermal fuse technologies, showcasing how they prevent motor burnout, extend equipment lifespan, and ensure industrial system stability through precise temperature monitoring.

In the world of industrial automation, the electric motor is the undeniable “heart” of operations. However, continuous operation, variable loads, and cooling failures can cause the motor’s core temperature to skyrocket, leading to catastrophic failures like insulation breakdown, coil burnout, and even fire. The motor overheat protector is a dedicated safety device designed to prevent these disastrous outcomes. But how does it work?

The Critical Need: Why Your Motor Needs a “Thermometer”

Motor overheating is often caused by overload, lock-rotor conditions, poor ventilation, or voltage irregularities. Excess heat rapidly accelerates the aging of winding insulation; for every 10°C over the rated temperature, insulation life can be halved. Installing an overheat protector enables:

- Prevention of Catastrophic Failure: Cutting power beforetemperatures reach a critical danger point.

- Reduced Downtime: Avoiding prolonged production halts caused by a completely burnt-out motor.

- Lower Maintenance Costs: Shifting from expensive motor rewinding or replacement to a simple protector reset or swap.

Core Working Principles: Two Primary Guarding Technologies

The market primarily offers two types of motor overheat protectors based on different technologies:

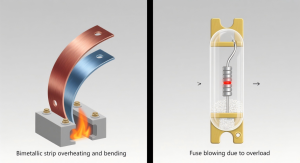

- Bimetallic Strip Type (Thermal Protectors)

This is the most common and cost-effective solution. Its core component is a bimetallic strip made from two bonded metals with different thermal expansion rates.

- How It Works: When the motor temperature is normal, the strip remains flat, and the circuit is closed. When the motor temperature rises to a preset value due to a fault, the two metals expand at different rates, causing the strip to bend like a snap-action disc. This physical deformation pushes the electrical contacts apart, forcing the circuit open.

- Cooling & Reset: Once the motor cools down to a safe operating range, the strip returns to its original shape, allowing the contacts to close and restore power (auto-reset models). Some designs require a manual reset (manual-reset models) for enhanced safety.

- Key Features: Simple construction, low cost, high shock resistance, and fast response as it directly senses the motor’s temperature.

- Thermal Fuses (TCO – Thermal Cut Off)

These are one-time-use, non-resettable devices offering ultimate fail-safe protection.

- How It Works: Its interior contains a temperature-sensitive pelletmade from a special alloy. At normal temperatures, it remains solid, keeping the circuit connected. If the motor temperature abnormally exceeds the fuse’s rated trip temperature, the pellet will rapidly melt and separate, permanently breaking the circuit.

- Key Features: Extremely high trip accuracy, absolute reliability (no risk of accidental reset), and low cost. However, it must be replaced after activation and is often used for ultimate backup protection.

How to Choose the Right Protector for Your Motor?

Selecting the appropriate thermal protector is critical. Consider these factors:

- Motor’s Rated Current & Voltage: The protector’s electrical ratings must match.

- Motor’s Insulation Class (e.g., Class B, F, H): The protector’s trip temperature must be aligned with the motor’s thermal endurance.

- Application & Reset Needs: Is automatic recovery acceptable, or is a manual reset required for safety?

- Installation Method: Will it be embedded directly into the motor windings or mounted on the surface?

ChuanCheng‘s AH9 Series Overheat Protectors utilize high-quality bimetallic strip technology. They are available in both auto-reset and manual-reset models, offering precise trip temperatures and fast response. Designed specifically for industrial motors in pumps, fans, and compressors, they are the ideal choice to ensure continuous and worry-free operation of your equipment.

Conclusion

Understanding how motor overheat protectors work is the first step toward ensuring industrial safety and reliability. Whether it’s a resettable bimetallic protector or a one-time thermal fuse, these devices act as silent guardians of motor “health,” serving as a key component for predictive maintenance and safe operations.